Selective Laser Sintering (SLS) 3D Printing Services

Our Process

How We Work?

Get a Quote

If you're looking for a better service, please request a quote.

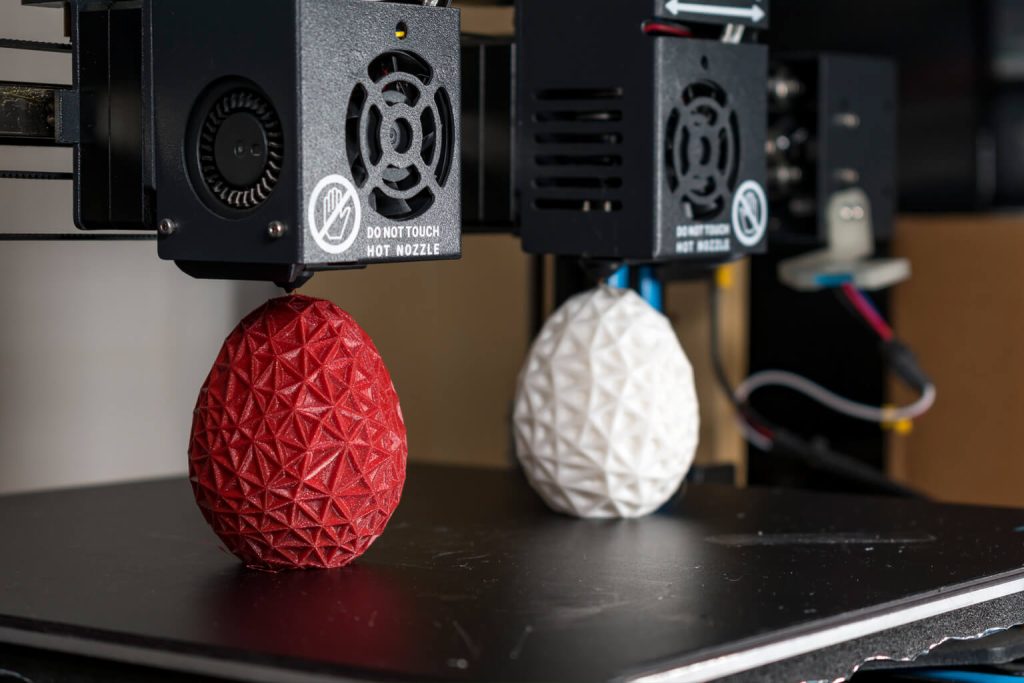

Review Your Design

We present you with a prototype of your 3D design; your feedback is requested.

Receive Your 3D Print

Get the desired results with the final printed version of your 3D design.

About SLS

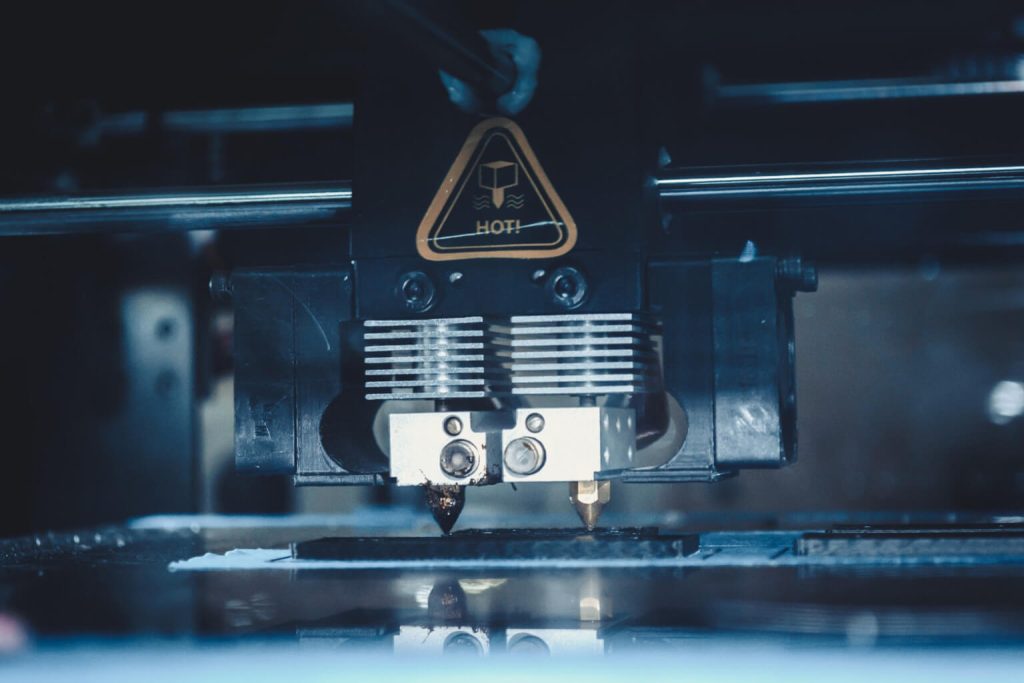

Selective laser sintering (SLS) is a cutting-edge 3D printing technology that uses a laser to selectively fuse powdered materials together, layer by layer, allowing for the creation of intricate geometries and internal structures that traditional manufacturing methods struggle to produce. This opens up a wide range of possibilities for product development, prototyping, and the creation of custom parts and components. Benefits of SLS includes the ability to create detailed and complex objects with high precision, combining flexibility with strenth and durability.

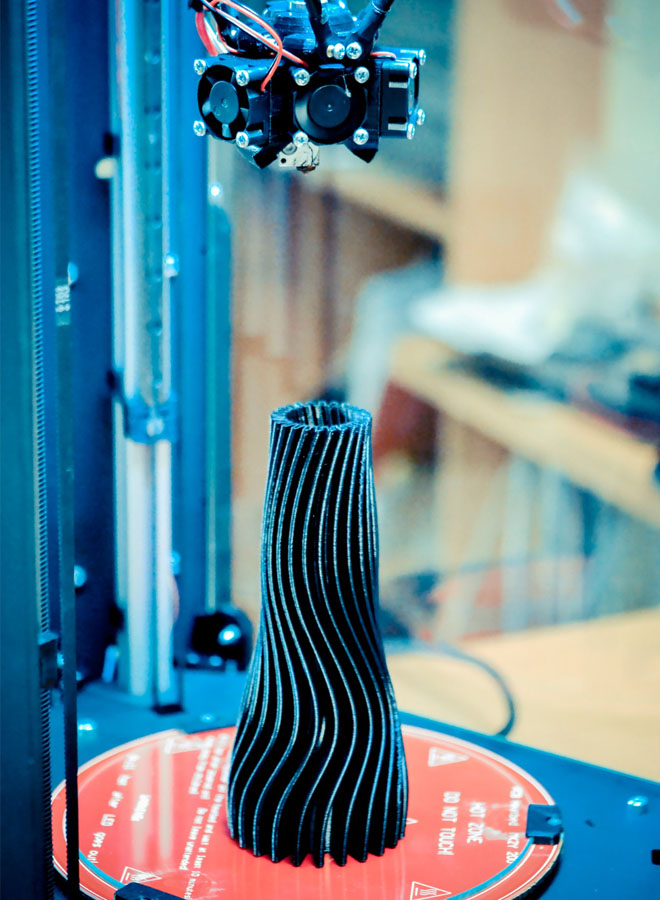

SLS Applications

Selective Laser Sintering (SLS) is a popular 3D printing technology that uses a high-powered laser to selectively fuse small particles of powdered material into a solid object. This technology has a wide range of applications and is commonly used in manufacturing, engineering, and prototyping.

- Custom prostheses and implants;

- Complex lightweight parts for aerospace applications;

- High-performance components for the automotive industry;

- Consumer goods and electronic devices;

- Detailed and intricated sculptures and artworks.

SLS Printing Services & Reseller

At Global3D, we understand the importance of SLS 3D printing technology in a variety of industries. We are experts in the field and specialise in providing SLS printing services to the medical, aerospace, automotive, consumer goods, and art and design sectors, to mention a few. We have a deep understanding of the SLS printing market and the various applications of this technology.

Additionally, we act as resellers for the top-of-the-line SLS printing machines, providing our clients with the latest equipment and technology to meet their specific needs. With our expertise and state-of-the-art technology, we can help our clients bring their most complex and demanding projects to life.

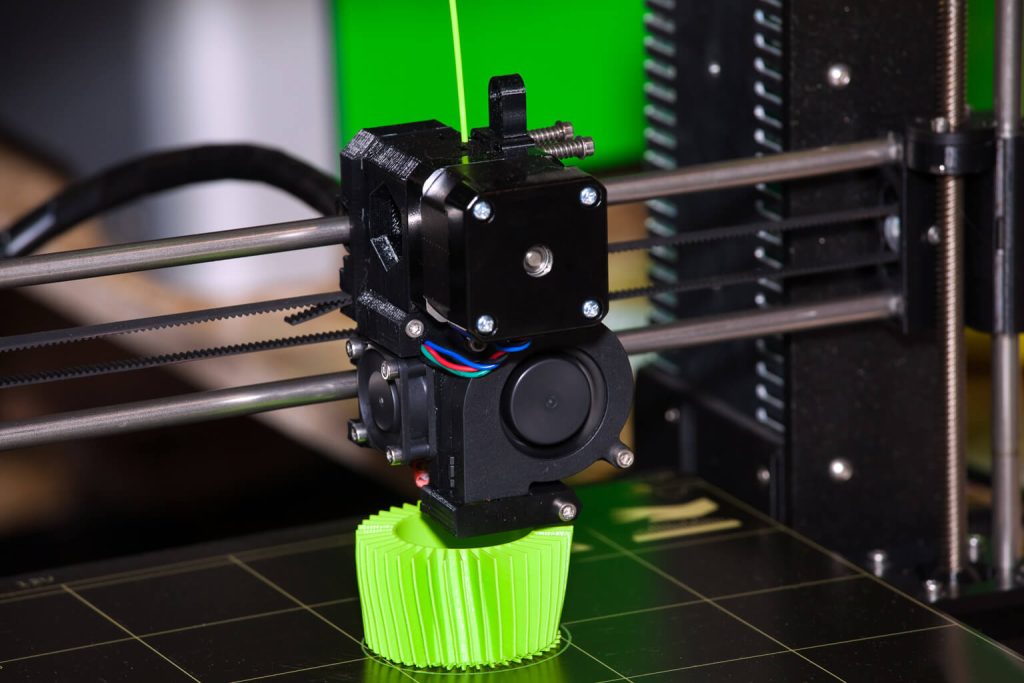

Develop your own capabilities with these machines

You can improve your skills and capabilities by using specific machines. Examples include 3D printers, CNC machines, and other manufacturing equipment that enable users to create and develop new designs and prototypes. By mastering the operation of these machines, individuals can expand their capabilities and improve their skills in various fields, leading to increased opportunities and growth.