Engineering Applications of 3D Printing

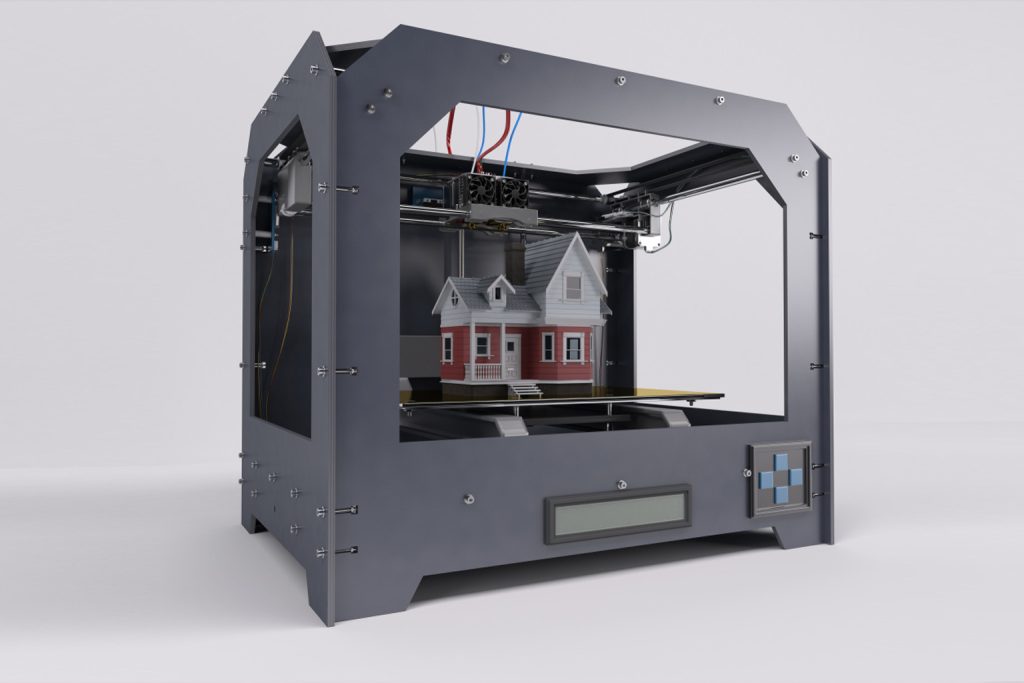

3D printing technology is revolutionizing the engineering industry by allowing for faster prototyping and the production of complex and customized parts. Our 3D printing solutions and 3D printers are designed to meet the specific needs of the engineering industry, from prototyping to mass production. With 3D printing, engineers can quickly create functional prototypes, test designs, and produce end-use parts with precision and accuracy.

Applications

Prototypes and concept models: 3D printing technology can be used to quickly create functional prototypes and concept models, which can be used for testing and evaluation.

Jigs and fixtures: 3D printing can be used to create jigs and fixtures, which can improve the efficiency and precision of manufacturing processes.

Tooling and molds: 3D printing can be used to create tooling and molds, which can be used for casting and injection molding.

Customized parts and components: 3D printing can be used to create customized parts and components, such as gears, bearings, and actuators, that are tailored to specific needs and requirements.

End-use parts: 3D printing can be used to produce end-use parts, such as structural components, mechanical parts, and functional prototypes, which can be used in a variety of applications, including aerospace, automotive, and construction.

3D printing can be used to produce jigs, fixtures and tooling, which can improve manufacturing efficiency and reduce costs. Our 3D printers can handle a wide range of engineering materials, including metals, plastics, and composites, making it possible to produce parts that are suitable for a wide range of applications.

With our expertise and experience, we can help engineering companies improve efficiency, reduce costs, and increase innovation. 3D printing is poised to play a major role in the future of the engineering industry. The future of 3D printing in the engineering industry looks very promising, as the technology continues to evolve and improve.

With advancements in materials and printing processes, 3D printing is becoming increasingly capable of producing parts that are stronger, more durable, and more functional than ever before. The ability to produce highly customized and complex parts quickly, and at a lower cost, is set to transform the engineering industry. As 3D printing becomes more widely adopted, it is expected to play an increasingly important role in the development of new products and the optimization of existing ones.

The technology can also be used to produce parts on demand and enable supply chain flexibility. The engineering industry is expected to continue to drive innovation in 3D printing and it will be an important tool for engineers to create new designs and bring them to life.

Develop your own capabilities with these machines

You can improve your skills and capabilities by using specific machines. Examples include 3D printers, CNC machines, and other manufacturing equipment that enable users to create and develop new designs and prototypes. By mastering the operation of these machines, individuals can expand their capabilities and improve their skills in various fields, leading to increased opportunities and growth.